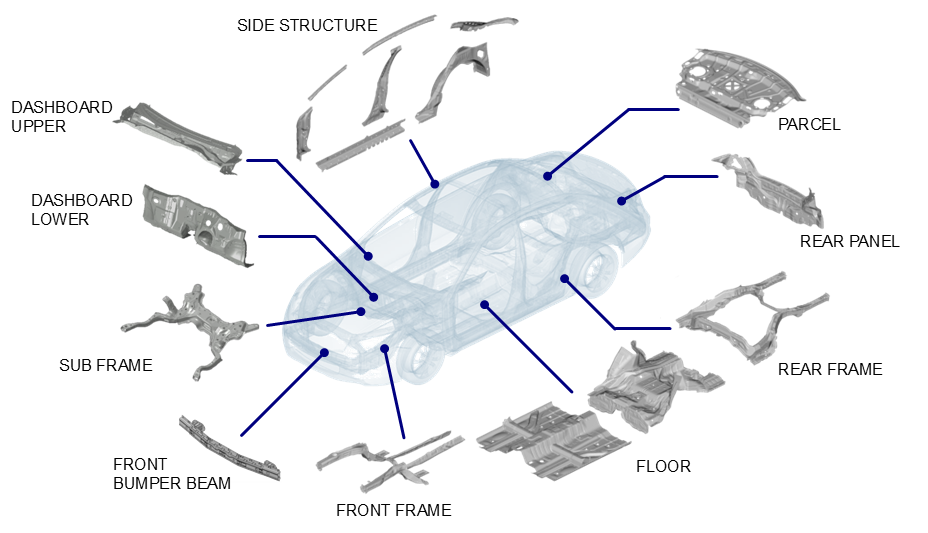

Vehicle Body Parts

Our core vehicle body products carry the vital mission of protecting occupants, and therefore must deliver exceptional strength. At the same time, weight reduction is essential to improve fuel efficiency and support environmental sustainability. More recently, higher rigidity has also been required to enhance ride comfort. Although these demands may appear difficult to achieve simultaneously, G-TEKT has addressed them by advancing high-tensile steel forming technology as well as mass-production technologies for hot stamping and aluminum materials. Looking ahead, we will continue to pursue vehicle bodies that are both lightweight and strong.

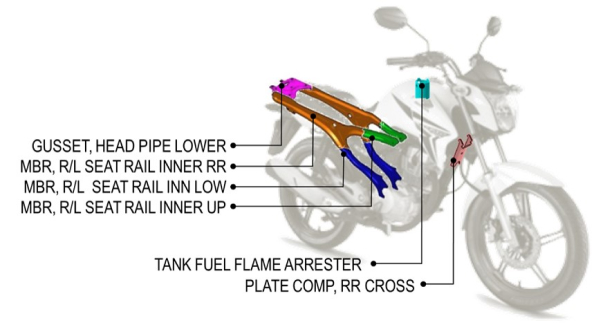

Transmission Parts

Our proprietary thickening technology significantly enhances design flexibility. By leveraging our accumulated expertise and experience, we meet customer needs from development through mass production—minimizing machining requirements and increasing component strength through work hardening.

We are accelerating the establishment of production technologies for the pinion gear (photo on the right), as one-shot forming enables significant process reduction and improved yield.

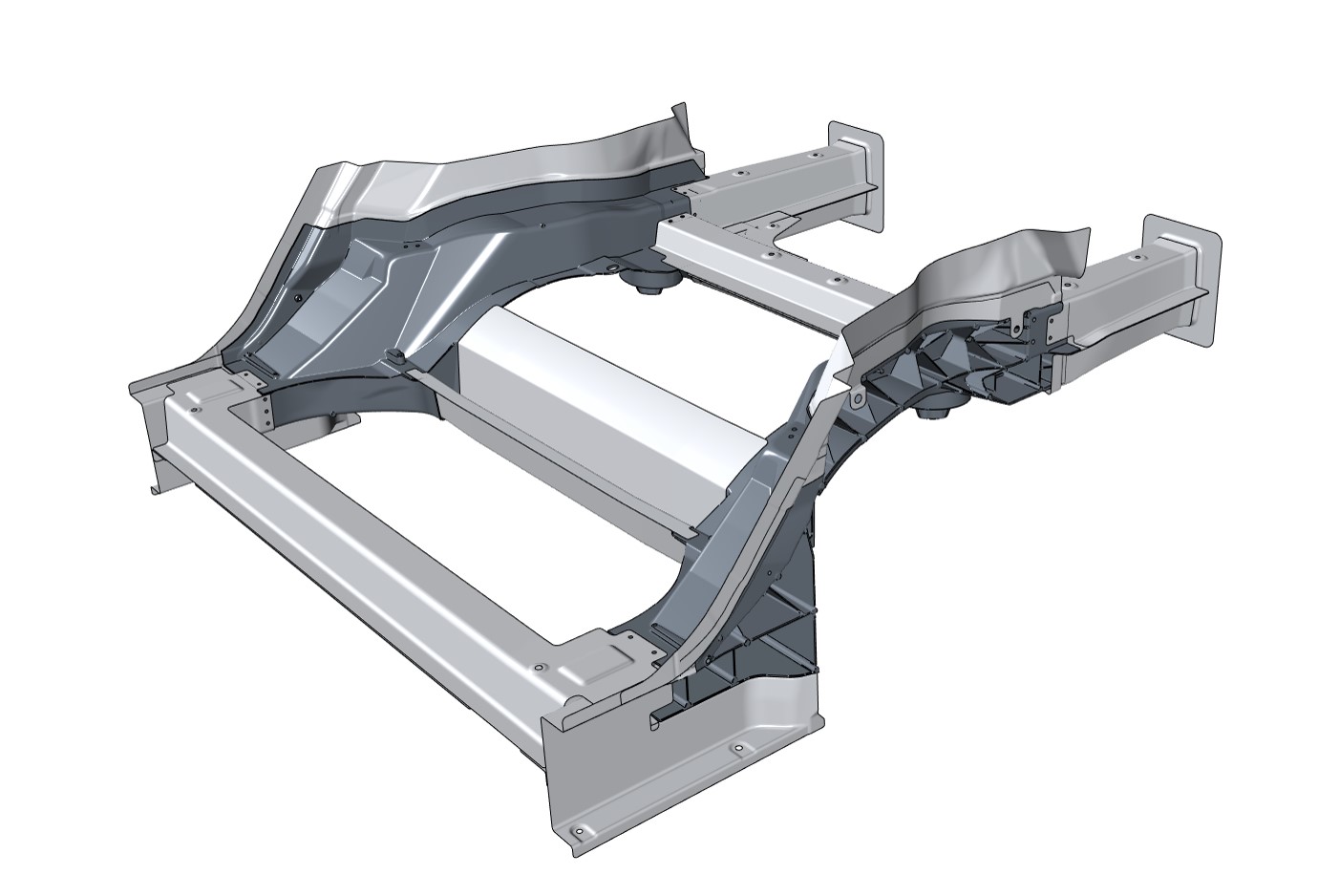

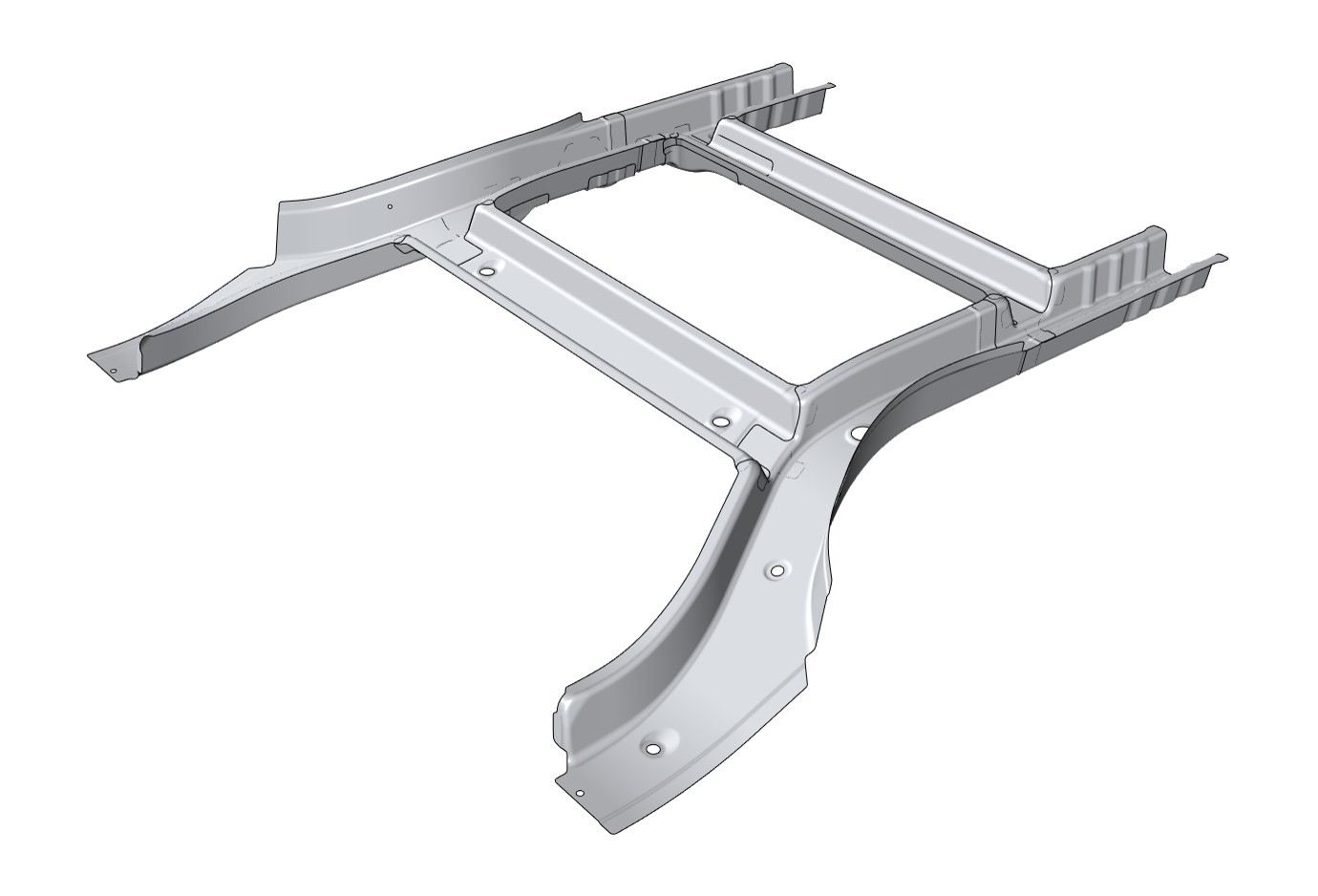

Large Integrated Module Parts

We are developing large modular products for vehicle bodies. By integrating multiple components, we reduce the total number of parts, streamlining processes for both automobile manufacturers and our own operations. These products offer various advantages, including weight reduction and lower CO2 emissions.

Door Ring

Steel

As the name suggests, a door ring integrates the sections where doors are mounted into a single, ring-shaped component. At our North American facilities, we are already mass-producing hot-stamped versions, delivering high-strength, lightweight products to customers. This is one of the components expected to see growing demand in the future.

Rear Frame

Multi-material specification

Aluminum × Steel

Hot stamping specification

Steel

G-TEKT has developed two types of rear modules to meet diverse customer needs. Both significantly reduce the number of parts and are ready for immediate practical application. The multi-material specification incorporates partial use of aluminum die-casting, providing greater design flexibility. The hot stamping specification delivers high productivity and excellent weight reduction.

Stamping Dies and Welding Equipment

Press dies form complex, high-precision shapes from a single steel sheet, while welding equipment assembles these pressed parts quickly and reliably. Together, they represent the core technologies that underpin the quality and productivity of our products. Press dies are designed in our die manufacturing division using CAE simulations, enabling both mass‑production capability and high forming quality. We design optimal welding lines tailored to part configurations and production requirements, and independently plan, propose, and construct high‑efficiency lines in an integrated, end‑to‑end manner. We also actively expand our external sales business for welding equipment, leveraging the technologies and expertise developed in-house.

Initiatives for Electrification

In recent years, the global shift toward electrification has been accelerating, and G-TEKT views this as a new business opportunity. We are advancing R&D and prototype development to expand orders for electric vehicle components, an area in which we previously had no production track record. Results are already beginning to emerge, and we will continue to deliver attractive products by responding flexibly to evolving business environments and customer needs.

Battery Housing and Battery Case

Steel

Aluminum × Steel

Aluminum

A battery housing is a box-shaped component that contains the batteries. It must provide sufficient strength to protect the batteries, while also being lightweight. To flexibly accommodate diverse OEM development concepts, G-TEKT offers a broad range of material and joining method options.

Side Frame (Roll Forming)

Side frames are long components placed on both sides of the battery housing to protect the battery from side impacts. While aluminum side frames are typically manufactured through extrusion, G-TEKT has achieved equivalent performance using roll forming—a process that gradually shapes material by passing it between continuous upper and lower forming rolls. These roll-formed side frames significantly reduce costs compared to extruded ones.

EA (Energy Absorption) refers to impact-absorbing members. To achieve weight reduction while ensuring high absorption performance against side impacts, G-TEKT has developed EA members that are incorporated inside the side sills.

Cell cases house individual battery cells containing electrodes and electrolytes and come in various types—including cylindrical, prismatic, and pouch—and are used in large numbers in electrified vehicles, including hybrid vehicles. Despite their seemingly simple shape, they require extremely high precision to ensure reliable sealing of their contents. G-TEKT has developed two types—one with a top lid and another with lids on both ends (double-sided opening)—to meet diverse customer needs.

Motor Cores

A motor core is the iron core that serves as the heart of an electric motor: the stationary side is called the stator core, and the rotating side is called the rotor core. Motor cores are typically produced by laminating thin steel sheets. G-TEKT is advancing R&D on both clinch-laminated and adhesive‑laminated motor cores; in clinch lamination, we have already achieved industry‑leading processing speeds while meeting stringent quality requirements. We have also established a prototype assembly line capable of assembling motor cores together with surrounding components.

As a related initiative, we are also promoting the in‑house development of winding technologies to support wound‑field motors—which do not use magnets and instead generate rotation by supplying current through wound copper coils (photo on the right). We are evaluating proprietary winding methods that enhance coil density and volume, both of which have a significant impact on motor performance, while also considering productivity.