Long-Term Vision

Vision Technology Innovation Sales Innovation Human Resource Innovation Business Strategies for Realizing Our Growth Strategy

Vision for 2020 – New G4-20

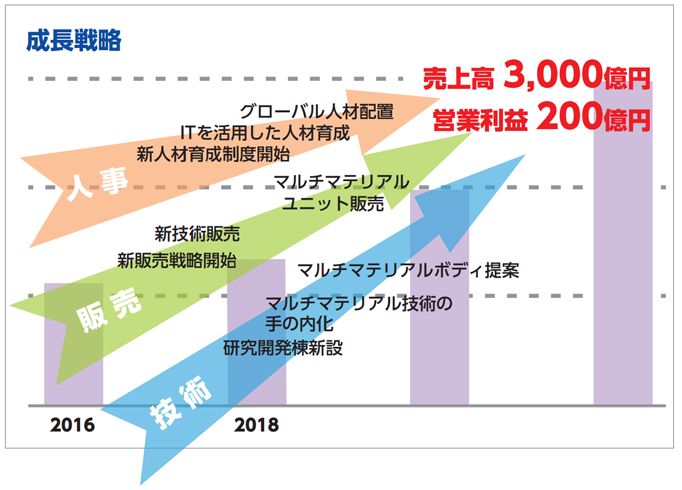

We have been using G4-20 as our year 2020 vision to become a leading global company. However, entering the third period of G4-20, we added three innovations, as well as sustainable growth and evolution, to accelerate progress in four domains: genba (on-site, hands-on), global, grow-up, and green.

The three innovations are technology innovation for creating unparalleled competitiveness in future mobility systems, sales innovation for delivering superior products to customers around the world, and human resource innovation for developing the talent that drives our efforts.

These innovations will lead to sustainable growth and evolution over the long term.

Vision

As the clear goals for G4-20, we have established specific targets to be achieved by 2022: consolidated sales of 300 billion yen and consolidated operating income of 20 billion yen.

We will proactively work on innovations in the three areas — technology, sales, and human resources — to hit these targets as well as to further reinforce our corporate structure.

In recent years, the automotive industry has seen increased global competition coupled with the urgent need to develop autonomous vehicles for mobility systems as well as information systems for transportation networks that control and direct shared-use vehicles. What’s more, the automobile is facing a major turning point due to the electrification of powertrains driven by the growing demand for EVs and fuel cell vehicles.

To accurately assess these new directions and to realize sustainable growth, we will need add new technologies to our core auto body technologies, as well as reinforce our corporate structure so that we can swiftly respond to changing times.

As a result, we have established new quantitative management targets as long-term management benchmarks: sales of 300 billion yen and operating income of 20 billion yen. To achieve these targets, will focus on three types of innovation.

Technology Innovation

G-TEKT TOKYO LAB (GTL)

G-TEKT TOKYO LAB (GTL) began operations in April 2018 as a research lab focused on developing innovations in multi-material technologies.

This research lab was established based on two concepts: to “accelerate technology innovation in a new research environment” and to “establish an attractive research environment to secure creative talent.” This all-new research environment will have employees with new ways of thinking as well as cutting-edge facilities and leading technological information exchange from collaborations with research offices in the United States, Germany and China. This will help to speed up R&D and ensure that this lab becomes a hub for raising our competitiveness and ensuring our sustainable growth and evolution.

Using Multi-Materials

Today, car bodies have undergone a revolution in the materials used. These include steel and aluminum, as well as aluminum, steel, and CFRP (carbon fiber reinforced plastic), among other combinations, for the desired goals of lightness and strength.

G-TEKT aims to develop technologies for the next generation of car bodies and keep these in-house, based on the key concept of multi-material solutions. For this goal, we will refine our hot stamp and mollification technologies for a fuller, more complete use of steel. At the same time, we will develop aluminum and CFRP forming technologies and technologies for joining materials, such as steel and non-ferrous materials, to create the lighter, stronger products of the future.

Sales Innovation

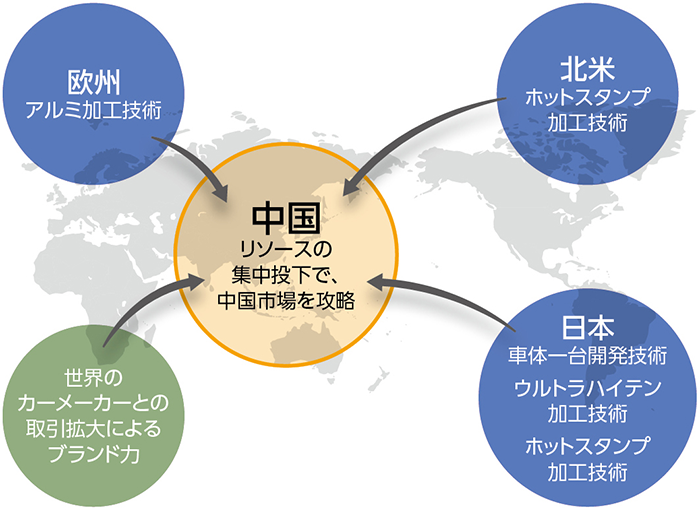

We will end our Japan-centric style of sales and marketing and build a new global sales structure that connects geographic regions. The headquarters in Japan will plan the sales strategy that will be jointly implemented with regional headquarters. Under this new sales structure, we will focus more on global automakers in Europe and the United States and deliver high-quality products to customers around the world.

The technologies and product strengths gained through business with global automakers will be shared with G-TEKT’s development and technology teams to spiral up the growth of technologies for creating and proposing even more competitive products.

Specifically, we will increase sales mainly to automakers that we have worked with in the past, targeting regions where G-TEKT is now, but has yet to do extensive business. The twin goals are to expand sales to global automakers from major markets to regional markets, at the same time as we expand sales from regional to major markets.

Human Resource Innovation

We have significantly revamped our human resource system by eliminating the seniority system in favor of a fairer, performance-based system. Also, our new human resource development program now provides systemized training instead of conventional on-the-job-training where workers learned through observation.

The new human resource system and development program reinforce the G-TEKT career model. The new human resource system uses more rigorous evaluations that reflect individual performance. The new development program uses a varied curriculum for methodical training. Comparing individual skill levels with G-TEKT’s career model will help us to identify the skills necessary for the future and provide the training needed to acquire these skills.

We will also introduce a human capital management (HCM) system as a new initiative for human resource development. Up to now, human resource development was difficult. However, by adopting HCM we will now be able to identify the skills needed for the future as well as the strengths and weaknesses of individual employees. Human resource innovation will empower us to nurture the talent that will generate new value required for the coming years.

Business Strategies for Realizing Our Growth Strategy

The automotive industry today is faced with a major, once-in-a-century turning point. Electrification, or making EVs, is speeding up in Europe and China, causing growing demand for auto body components that are lighter and stronger. For this business climate, G-TEKT is proactively deploying various business strategies to realize growth.

Weight Reduction Strategy — Technology for Door Rings Using Hot Stamping

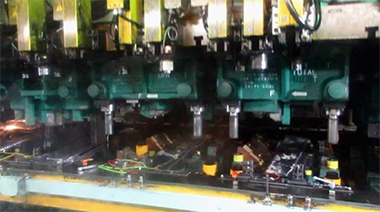

G-TEKT has successfully created technology, using hot stamping, that forms all the parts of the entire side structure of a car at the same time.

As a result, we are the first Japanese manufacturer to establish a timeline for the start of mass production.

In the past, side structure components were assembled by welding together multiple pressed parts made from high tensile strength materials. Our technology allows us to form the entire side structure of a car using strong, light hot stamped materials instead of multiple high tensile parts, helping to further reduce weight.

This also eliminates the need for joints that connect parts, making auto body components much stronger. The hot stamping process also boosts productivity by reducing the number and area required for welding lines.

Weight Reduction Strategy and Sales Strategy for Next-Generation Auto Bodies

Today, the methods employed to reduce weight using steel include hot stamping and super high tensile strength materials. To come out on top in the coming era of electrification, auto parts need to be even lighter by using non-steel materials, especially aluminum. G-TEKT will build up mass production technologies for aluminum auto body components in Europe, where there is growing demand for lighter aluminum designs. Using these technologies, we also plan to expand our business presence in China, the world’s largest market. The information below introduces some of the initiatives currently taking place.

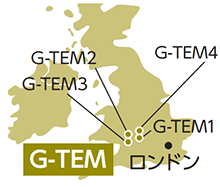

New No. 4 Plant at G-TEM in the U.K.

G-TEKT will construct the new No. 4 Plant at G-TEM in Gloucester, U.K. to increase production capacity to accommodate a growing number of local orders from Toyota and Jaguar Land Rover.

In Europe, we will introduce production plants that can handle mass production and the processing of aluminum components given the large number of business inquiries for aluminum auto body components. Later on, we will build up our experience and know-how in this area.

Further, expanding this plant will ensure that G-TEM plays a leading role in swiftly and accurately meeting the growing need for next-generation aluminum auto body components in Europe.

| Location | Gloucester, U.K. |

|---|---|

| Start of operations | Scheduled for January 2019 |

| Site area | approx. 41,000 ㎡ |

| Floor space | approx. 12,000 ㎡ |

Establishment of G-TES in Slovakia

In Slovakia, G-TEKT will establish G-TEKT Slovakia, s.r.o. (G-TES) and build a new plant to handle the growing number of orders from Jaguar Land Rover for aluminum components.

This plant will introduce production equipment for aluminum components similar to G-TEM in the U.K. and begin operating as our first and the first full-fledged aluminum auto body component mass production plant operated by a Japanese auto parts manufacturer.

Taking full advantage of Slovakia’s location as a central hub in the European auto industry, G-TES will use a two-tiered system, together with G-TEM in the U.K. as another hub, for producing aluminum auto body components that will increase sales to automakers in nearby countries. Both hubs will work to improve their mass production technologies for multi-material aluminum auto body components and steadily, consistently grow our presence in Europe.

| Location | Nitra, Slovakia |

|---|---|

| Start of operations | Scheduled for June 2019 |

| Site area | approx. 100,000 ㎡ |

| Floor space | approx. 15,000 ㎡ |

Opening the Shanghai Research Office and Building the New No. 2 Plant of WAPAC

Similar to Europe, China has seen growth in the EV segment. As a result, we opened the G-TEKT Shanghai Representative Office (GSR) to investigate local needs and to conduct market research. GSR will help spearhead our efforts to formulate and roll out an aggressive business strategy that accurately identifies the ever-changing trends in the Chinese market.

Moreover, we decided to build the new No. 2 Plant for WAPAC (Wuhan, Hubei Province) in Changsha, Hunan Province to boost profitability using improved efficiency for logistics following an increase in orders from an existing customer: GAC Mitsubishi Motors.

The suburbs of Changsha have many local automakers and Chinese joint ventures with European automakers, including some of China’s largest green vehicle manufacturers. Going forward, we will employ our mass production technologies for aluminum auto body components in the U.K. and Slovakia as well as the information collected by GSR to speed up the growth of new business in the Chinese market.

| Location | Changsha, China |

|---|---|

| Start of operations | Scheduled for April 2018 |

| Floor space | approx. 69,000 ㎡ |

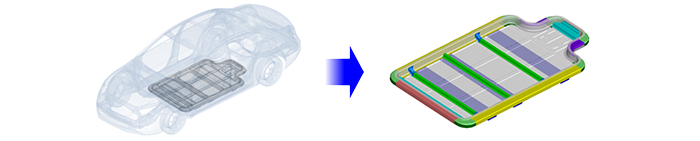

Electrification Strategy — Developing Lightweight Battery Pack Cases —

Electric vehicles require a large number of batteries that are heavy and in a pack that needs to be both large and strong. Battery packs must also have anti-corrosion coatings on cases to prevent rust.

G-TEKT has begun developing lightweight, rust-proof cases for battery packs made mainly of aluminum for the next-generation of EVs.

This development is taking place at GTL, our research hub in Tokyo, and involves combining our experience of manufacturing cases for battery packs with aluminum processing technologies.